50€ per year to heat your home

Blog

50€ per year to heat your home

Is it true what they say, that passive houses use very little energy and are super comfortable? This article presents monitored data from a Passivhaus-certified home, located in the town of Collsuspina, province of Barcelona, at 888 meters above sea level. The results show a heating bill of 50€ per year, a high level of comfort in both winter and summer, and a good indoor air quality.

Figura 2: Placa de certificació Passivhaus

Figura 1: Imatge de la façana sud & oest

Figura 3: Detall de finestra y façana ventilada de làrix

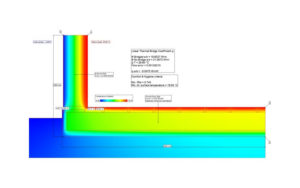

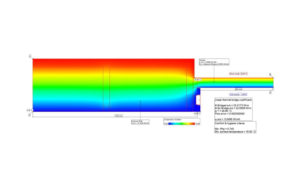

Figura 4: Càlcul de pont tèrmic, Solera > Mur façana

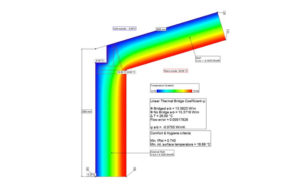

Figura 5: Càlcul de pont tèrmic, Mur façana > Coberta

Figura 6 Càlcul de pont tèrmic, Finestra – Brancal

Figura 7: Localització de sensors a la planta baixa

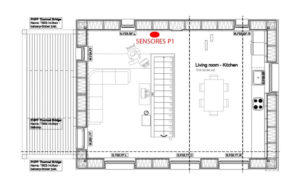

Figura 8: Localització de sensors a la planta primera

Figura 9: Sensor de temperatura i humitat exterior

Figura 10: Sensors de temperatura, humitat i CO2, planta baixa

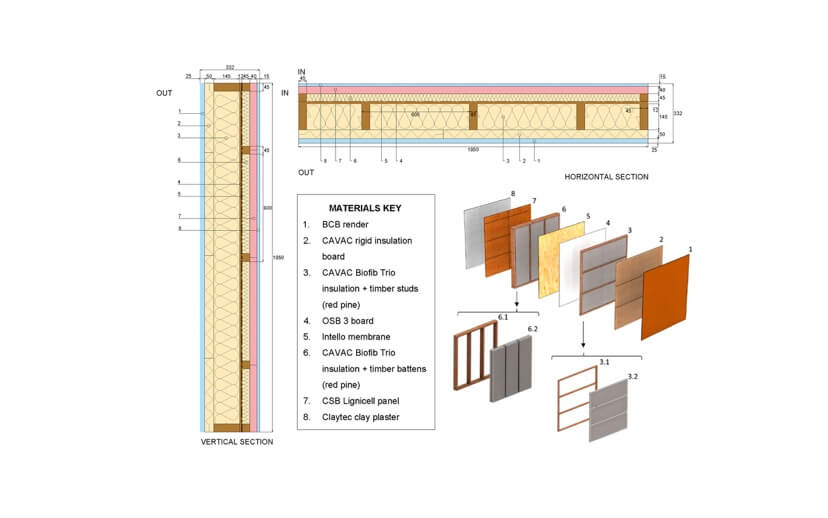

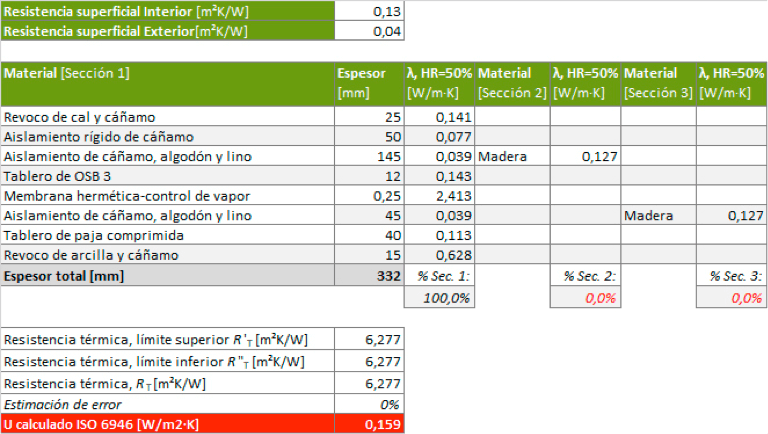

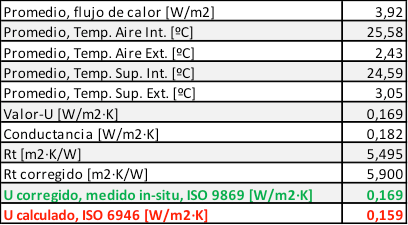

Table 1 shows the characteristics of the thermal envelope, heating, hot water and ventilation systems.

| Ground floor slab | U = 0,164 W/m2·K |

| External walls | U = 0,146 W/m2·K |

| Roof | U = 0,147 W/m2·K |

| Windows | Uw instal·lada = 1,09 W/m2·K |

| Frames | Uf = 1,22 W/m2·K |

| Glazing | Ug = 0,60 W/m2·K ; g = 47 % |

| Shading devices | External venetian blinds & retractable awnings |

| Airtightness | N50 = 0,31/h |

| Mechanical ventilation | Zehnder ComfoAir 350 |

| Heating | Electric radiators |

| DHW | Airsource heat pump Aerotermo 300 Plus |

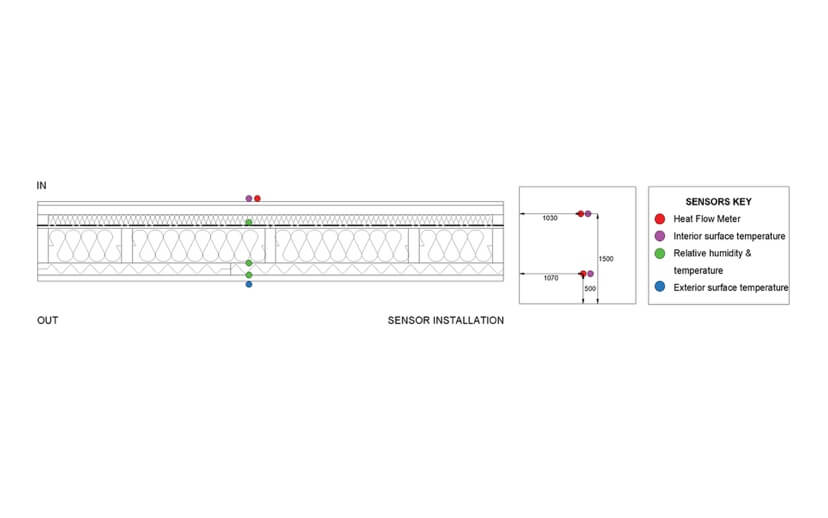

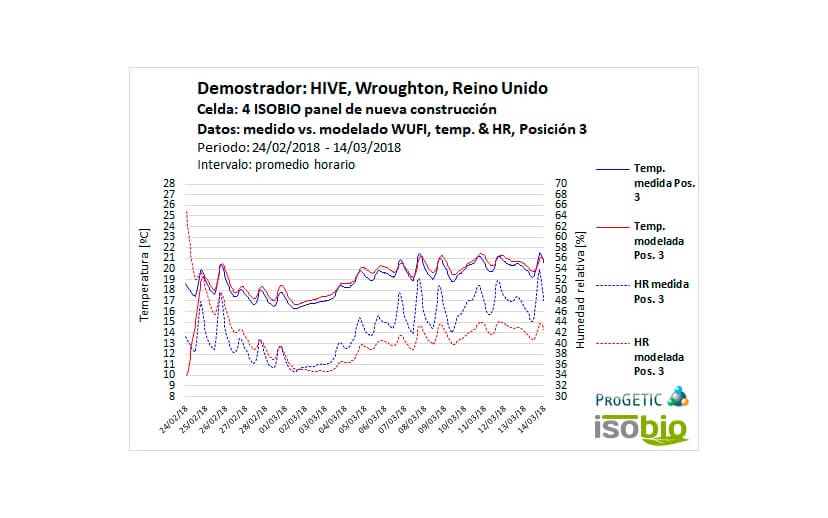

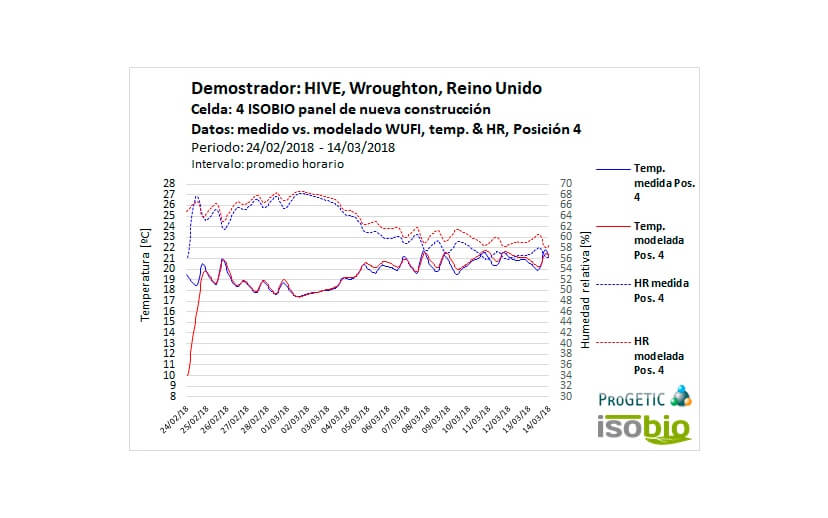

The house was built with a lightweight prefabricated timber system filled with straw insulation. On-site construction took 5 months. The home was monitored between 2015 and 2016, measuring outdoor temperature and humidity, and indoor temperature, humidity and concentration of CO2, on the ground floor main bedroom, and 1st floor sitting room (open plan, shared with dining room and kitchen). Electricity meters were also installed to measure the electrical consumption for heating (electric radiators), DHW (air source heat pump), mechanical ventilation and general electrical consumption (household appliances & lighting). Monitoring was self-financed between the following companies: Progetic, Farhaus, Zehnder Ibérica, with a contribution from the city council of Collsuspina. The house is occupied by 2 adults and 2 young girls.

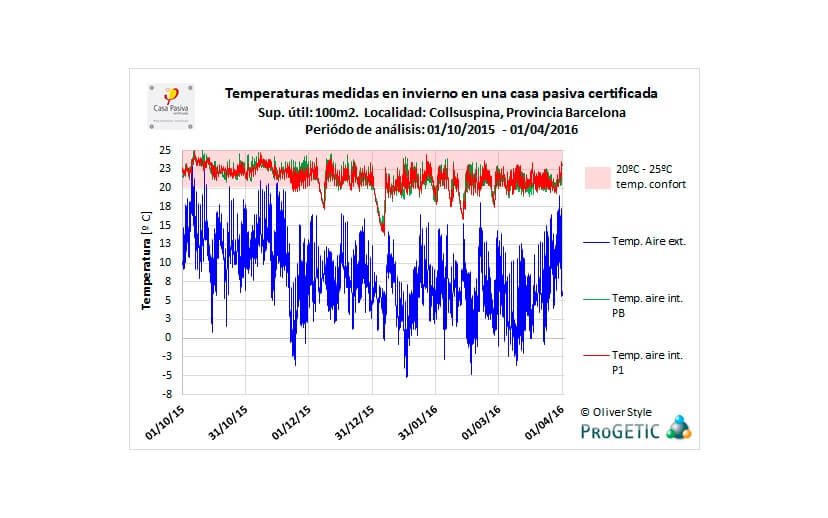

Winter comfort

Figure 12 shows the indoor temperatures on the ground floor and first floor, and the outside temperature, during the winter of 2015/2016. It can be seen that temperatures remain between 20 °C and 25 °C, except when the house is unoccupied. The average temperature on the ground floor in that period was 21.2 ºC, and 21.3 ºC on the first floor. The total heating consumption (electric radiators) in this period was 251 kWh, or 52€, calculated with a price of electric energy of € 0.21/kWh, according to actual bills. (The consumption results can be seen in Figure 16 and Figure 17).

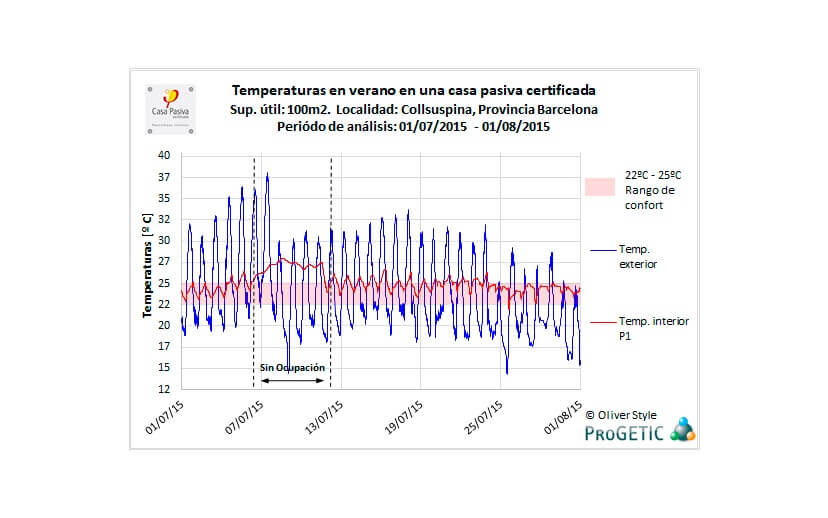

Summer comfort

Figure 13 shows the outdoor temperature and indoor air temperature on the First Floor (being the most susceptible to overheating), during the heatwave of July 2015. It can be seen that temperatures remain below 26 °C, except when the house is empty.

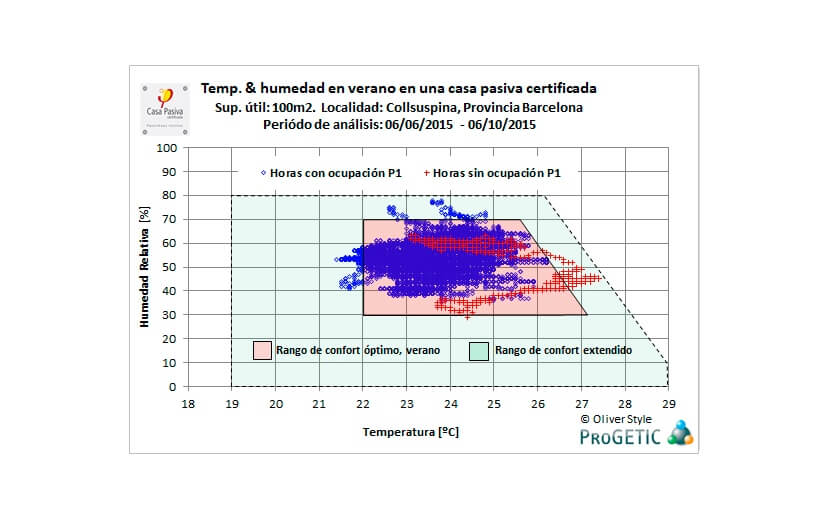

Figure 14 shows the temperature and relative humidity on the first floor, between June and October 2015, separated between hours with and without occupation. It can be seen that, during busy hours, the temperature and relative humidity are generally maintained within the optimum comfort range (22 ºC to 25 ºC at a relative humidity of between 30% and 70%, according to the comfort model of Dr. Schnieders, based on ISO 7730).

Indoor air quality

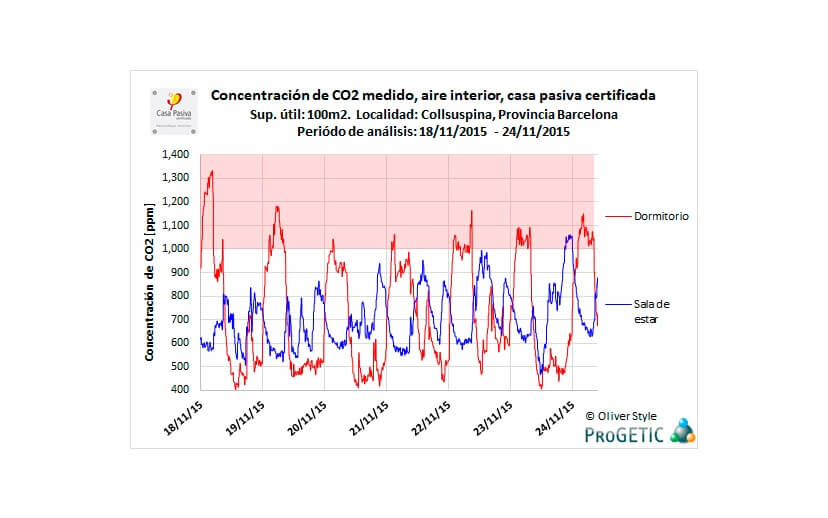

Regarding indoor air quality, measured through the concentration of CO2, Figure 15 shows the level of CO2 in the bedroom and in the living room, for a week in November 2015 (where no windows were opened for ventilate). It can be seen that the CO2 level exceeds 1,000 PPM at specific times, with an average of 722 PPM in the bedroom and 706 PPM in the living room. The results indicate a high quality of indoor air in winter.

Consumption & energy bill

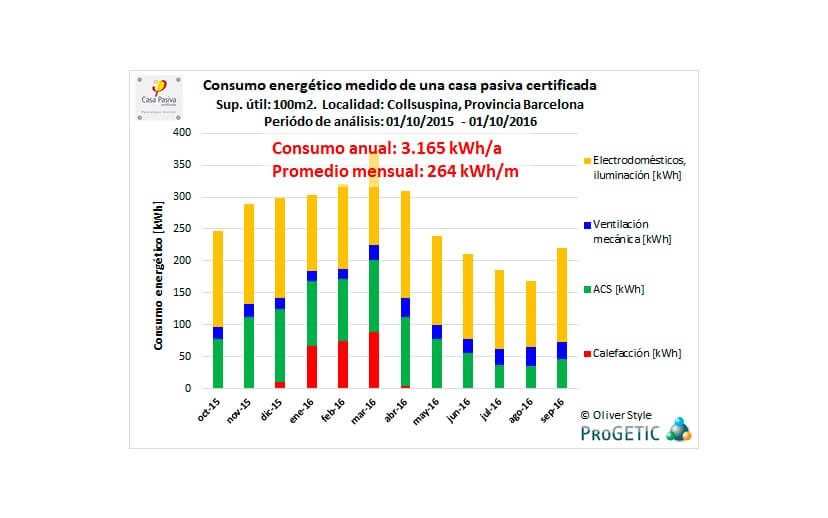

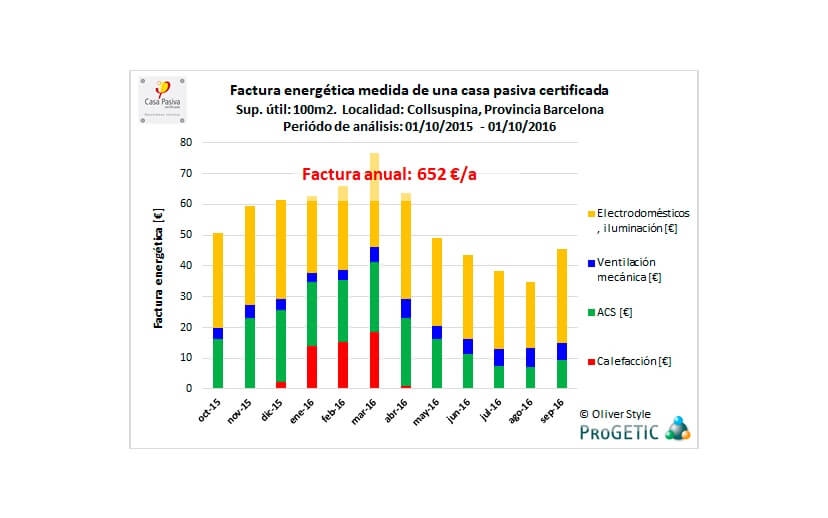

Figure 16 and Table 3 show the energy consumption by category, between October 2015 and October 2016. Heating consumption was 251 kWh (52€/year), 970 kWh for Domestic Hot Water (200€/year), 264 kWh for mechanical ventilation (54€/year), and 1,681 kWh for appliances and lighting (346€/year), with a total consumption of 3,165 kWh/year, or 652€/year.

Conclusions

The results indicate that the house has an almost zero energy consumption, a high level of comfort and a good indoor air quality. A larger study of Passivhaus buildings in Spanish climates is required to be able to further analyze the actual behavior. However, the results of this particular house are very positive.

It should be noted that, in the last instance, the energy consumption in a home depends on the performance of the users. In this case, users are very active, taking care of energy consumption, and lowering blinds in summer to avoid overheating. Another point to highlight is the openings surface: project reasonable openings and avoid large window areas, it is key to reduce overheating in summer, without active cooling. Finally, it is important to take into account that, for this climate is possible to maintain thermal comfort in summer without refrigeration, because temperatures tend to fall below 20 ° C at night, making heat evacuation effective by natural night ventilation. In climates where night temperatures remain above 22 °C with higher relative humidity (coast areas, for example), it is very difficult to maintain comfort during summer without active cooling and dehumidification.

Acknowledgments

Albert Fargas – Farhaus; Jordi Vinadé & Itziar Pagés; Ajuntament de Collsuspina; Zehnder Ibérica;